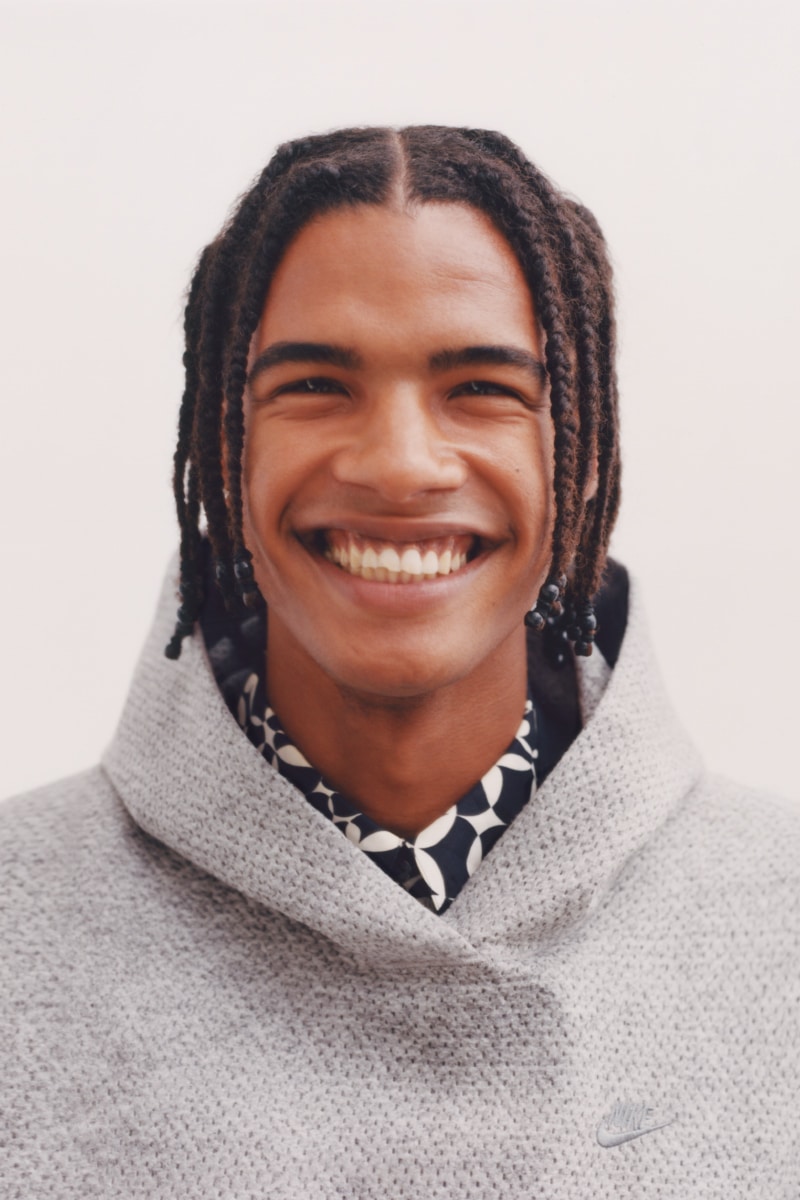

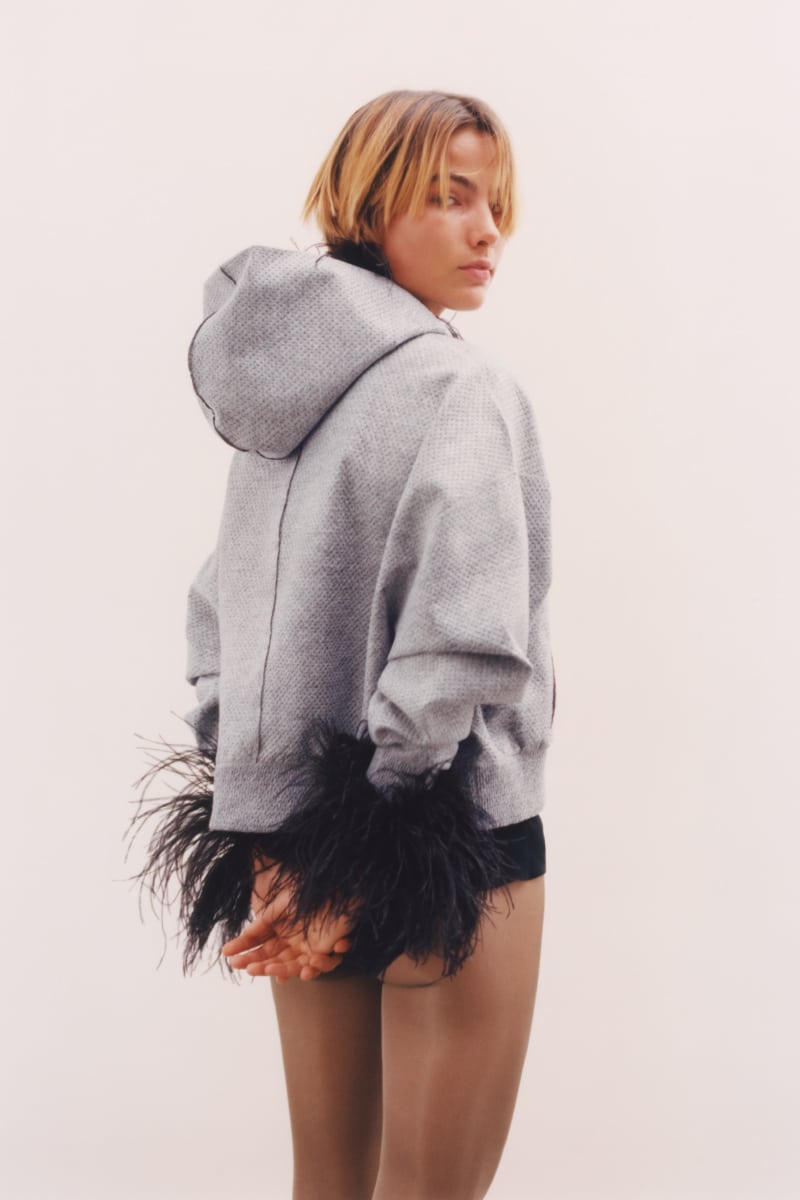

Fewer steps mean less energy consumption. Nike’s new Nike Forward is giving us a look at the future, where a clean slate aesthetic merges with clean out. Looking at their beloved hoodie silhouette, Nike Forward forgoes embellishments and dyes, favoring raw-cut pickets and zero water usage. Made without zippers, aglets, or extra trims, also makes it easier for the garments to be recycled.

The innovative Nike Forward material has seen 5+ years of research that challenges the extractive consequences of fashion to a more circular one by reducing the carbon footprint of its first-gen material by 75% by creating a new cycle that turns fiber (with a diverse range of layers, including industrial and post-consumer waste) directly to textile through needle-punch as opposed to the process of multistage (spin yarn, knit, cut, sew and more). We caught up with Nike to hear more about this groundbreaking new drop!

Fashion is so fast-paced, that sometimes there isn’t time for real innovation. Nike has been playing a bigger and bigger role in fashion in recent years, probably because it is a leader in innovation and doesn’t rush things until the technology is right. With that said, your Nike Forward material has seen 5+ years of research and development behind it. Can you tell us a bit about those five years and what does the stages and test and trials look like?

Whenever we’re innovating here at Nike we get on a journey of learning and challenges and Nike forward was no different throughout the five years of research and development. One of the biggest challenges we had was with the needle punching technology, we’ve borrowed this technology from other industries that are not apparel related and so much of our research and development, difficulties and challenges were spent around making sure that the material could deliver the performance that our Nike athletes demand, as well as the style and comfort and durability that they expect from Nike product. That was really where that art and science and a little bit of magic of Nike came together to make the first generation of Nike Forward possible today.

Talking about the fast speed of the industry, rather than moving forward and breaking things, we can move in forward in a different direction. What was the main problem that you wanted to solve and what would you say when critics complain that athletics aren’t helping by creating so much wear and tear their activewear that it ends up becoming one of the big problems?

We all have a role to play in combatting climate change. The faster we can collectively do more for the environment, the better it will be for generations to come. And as the biggest apparel company in the world, we have a responsibility to reimagine sustainable innovation and scale solutions to reduce our impact. We know that our competitors look to us for what’s next and we are proud to be in a position to set an example. Nike Forward is purpose-built to drastically reduce environmental impact and is an example of how we are accelerating our efforts to achieve our bold, science-based targets. Our goal is to create products that are better for performance and better for our planet.

We’re exploring circular solutions with technologies and materials that are lower-impact, longer-lasting, and more easily recyclable. We’re leveraging our digital advantage to help consumers easily shop for sustainable products and piloting retail concepts that will change how we make products, deliver them, and take them back for another life. We are also developing a portfolio of sustainability-oriented solutions across our value chain and advancing new circular business models. In the race against climate change, we aren’t waiting for solutions. We’re creating them.

We are getting to the end of what we can extract without deadly consequences. Nike Forward was created for circularity to help reduce environmental impact. “Circularity” can sound quite alien to many people. How is it circular and what is it made up of?

Circular design principles guided the innovation process. We reduced the carbon impact of Nike Forward materials by using recycled content as an input. Also, reimagining material construction and replacing traditional knitting and weaving with a needle-punching process that has fewer steps. We leveraged a way to create a color that reduces the energy typically required to dye material. Finally, the initial products made with Nike Forward feature no added embellishments, like zippers, or aglets, which reduces waste in the design process and makes garments easier to take apart and recycle at the end of use.

The process to create the first iteration of products made with Nike Forward materials uses no water in dyeing and finishing. Are you able to produce on a massive scale? What hurdles do you face or what did you expect to be difficult and find out was much easier in the end?

Yes, Nike Forward is scalable and that’s in part why we are so excited about it. Whenever we’re innovating here at Nike we get on a journey of learning and challenges and Nike forward was no different throughout the five years of research and development. One of the biggest challenges we had was with the needle punching technology, we’ve borrowed this technology from other industries that are not apparel related and so much of our research and development, difficulties and challenges were spent around making sure that the material could deliver the performance that our Nike athletes demand, as well as the style and comfort and durability that they expect from Nike product. That was really where that art and science and a little bit of magic of Nike came together to make the first generation of Nike Forward possible today.

Pierre Balmain said, “Good fashion is evolution, not revolution.” Nike has created a much simpler process—fewer steps—than knit or woven, which significantly reduces the carbon emissions of traditional Nike knit fleece. Starting with a composite of 5 thin layers, there’s limitless potential to change the makeup. Do you see Nike Forward as the first step for something larger in the industry? And how would you feel about more open-source solutions to the problems that fashion creates?

This is our biggest apparel innovation since Dri-Fit 30 years ago and we believe it has huge potential to transform the industry like Nike Air or Nike Flyknit did. We know that fighting climate change is a team sport and our collaboration with the industry happens on many levels. For example, we created the Supplier Climate Action Program (SCAP) with the help of trusted partners World Resources Institute (WRI), the leader in GHG emissions inventories, and CDP, the leading climate disclosure platform. The program encourages suppliers to address climate change strategically through development of their own long-term climate mitigation plans, while aligning with Nike’s Science-based Targets. And, our Circular Design Guide, created in partnership with students and academic staff at Central Saint Martins University in London, and inspired by the non-profit Global Fashion Agenda, is an example of how we’ve shared a circular approach to the design, manufacture and reuse of products with as little impact on the environment as possible.

From innovation to design, how did you want this first capsule to look? Are you looking for something timeless or had different colorways in mind?

The bold new look and feel of Nike Forward expresses this pursuit of a better future — a sophisticated ethos that honors the raw aesthetic of recycled materials, the restraint of additive elements and ways of caring for our garment. The first iteration of products made with Nike Forward materials uses solution dye. We are exploring sustainable options to introduce a variety of colors in future product made with Nike Forward.