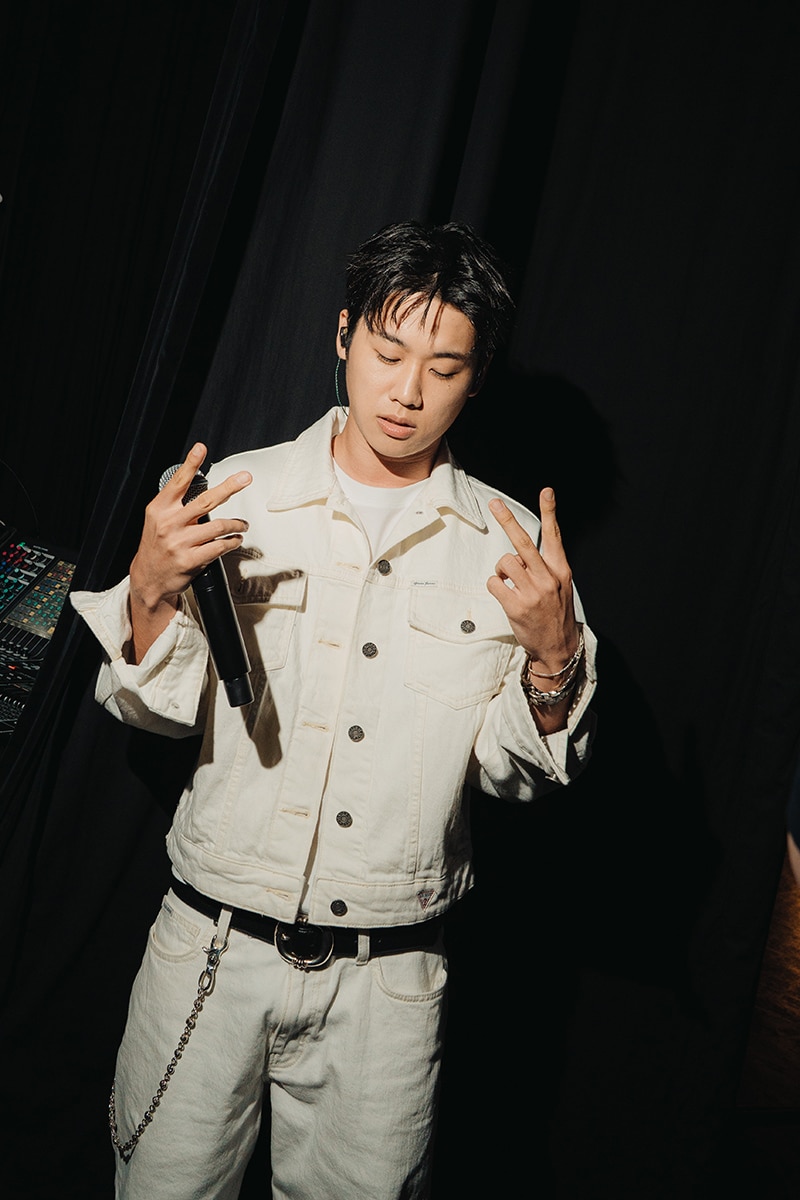

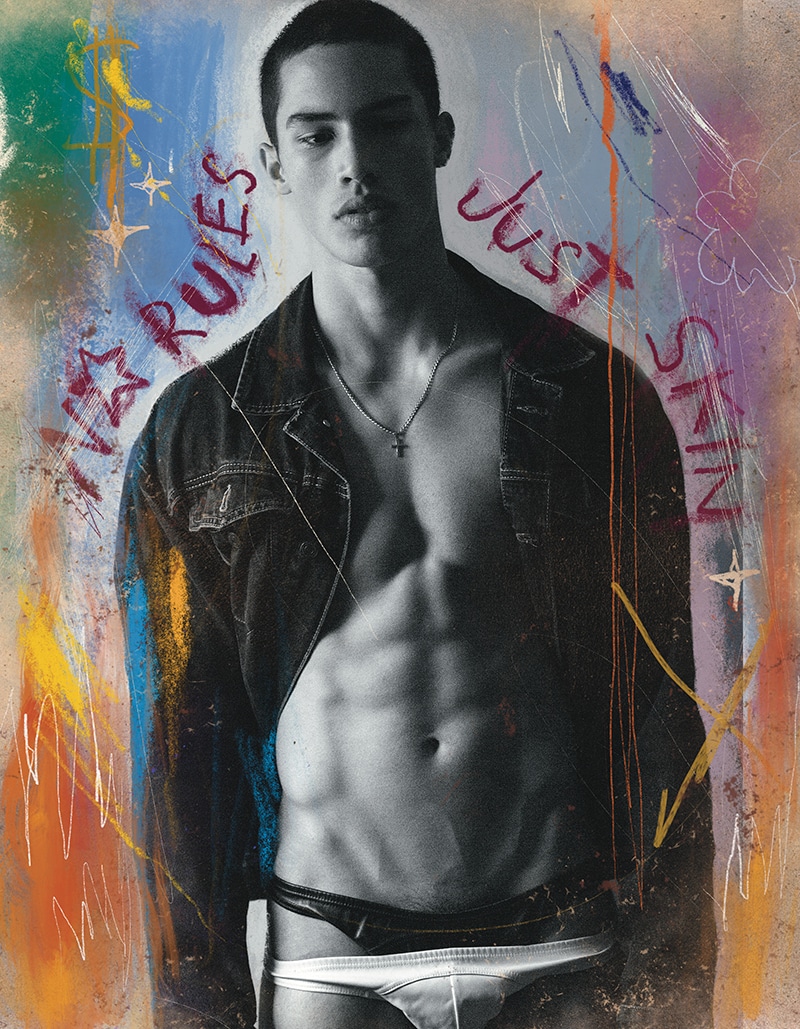

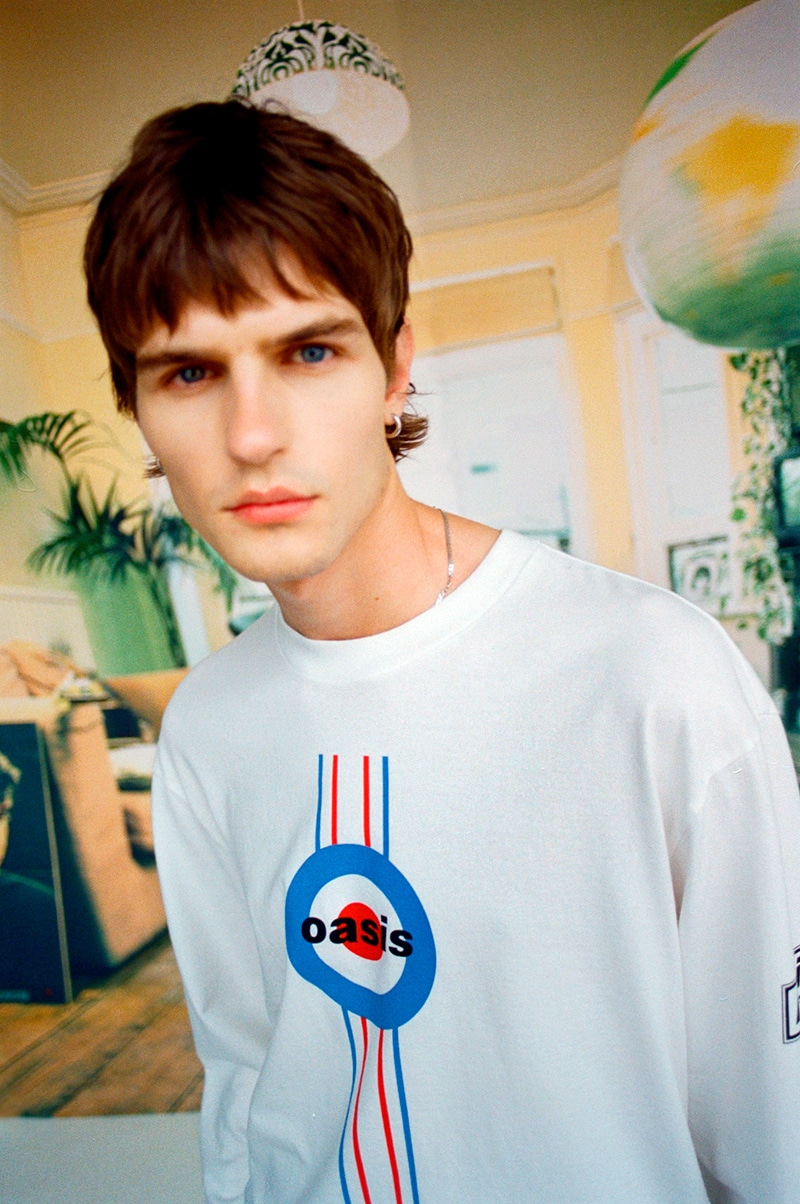

This generation is the most tech-savvy while being aware of wastage. The 3D Printing scene adds a new element to conversations. Diana Law is the first designer to use the future-wise technology for accessories offering sustainable creations with no fear while celebrating individualism. Defining a “Post-Fast Fashion” climate her work explores 3D dimensions through geometric lines and intricate forms uniting technology that used to be just in Couture shows now found on skaters and rappers.

You had a successful career in haute couture for private clients. Why abandon the most classical of techniques for technology with such an androgynous aesthetic?

The world is moving fast with technology and altered the way we think. Public embraces in new concepts and ideas. 3D printing certainly changed my visions in designing. So instead of doing the traditional, I moved onto something new and fresh.

You are based in Paris, but are originally from Seattle. A contrast of nature and technology. Did that have any influence on you?

Old and new are always a good combination for contrast. Certainly influenced my designs as they are inspired by the classics, reinterpreted by today’s vision and technology. Growing up in Seattle was a blessing, technology pretty much surrounded me and you learn at a young age that technology is the way forward. I mean literally, just about everybody around worked for either Boeing or Microsoft!

You started exploring 3D printing a few years ago, right around the same time as Iris Van Herpen, but you waited until recently to soft launch. What developments and changes happened in the field? Why wait?

The technology has experienced remarkable growth in the last five years and I think now is the time to do a soft launch as the public is growing interest with more awareness on the concept and idea. The technology has also refined to a point of end-use products, as opposed to years ago when it was primarily used for prototyping.

What’s the process when you make your pieces and how long does it take to print?

Different material requires different process and time. For example, the Strong & Flexible Plastic uses the SLS process (Selective Laser Sintering) and will take around 7-10 working days to print, depending on its size. This is the process that uses a laser to fuse together ultra-fine nylon powder, with each layer less than 0.1mm. The metal pieces, however, are produced differently. Printed Steel uses the Binder-based Jetting Systems, of which liquid binder is deposited onto a thin bed of steel powder one layer at a time until the design is finished. The piece is then carefully removed from the printer and infused with bronze in the infusion chamber. Due to longer processing time, it will take 10-15 working days to complete a metal piece.

We hear a lot about all of the possibilities in 3D printing, but you are one the few designers that don’t use it as a gimmick. What attracted you?

Haha I think the “endless possibility” part is a given. By all means, it does offer endless possibilities. However, being a fan of TED as I am, I went for the “question” angle instead. What is this? How is this made? Why is this technology better? What else is there? Completely fascinated by this, still to this day.

Do you pay attention to other developments in the field? What else is being printed?

All sorts of things are being printed! Items such as bikes, engines, houses, aircraft parts and even a bridge is being printed in Amsterdam as we speak. Exciting developments in 3D bioprinting and nano printing are also happening. Yes, printing of human cells (including stem cells) into complex functional living tissues. It’s pretty incredible as this technique is already in use for tissues and organs in need for transplantation. Then there is the 3D nano-printing that allows for rapid prototyping of micro and nano structures. In simpler terms, imagine a normal battery that is the size of a single grain of sand! It is absolutely mind-blowing.

When you started, what materials were available to you? Or were you creating your own?

I started off with Strong & Flexible Plastic (a very versatile plastic that is extremely flexible when used as wires but strong enough to also be used as structural components), as well as Steel. Now Steel printing is quite interesting as it offers extreme accuracy and detailing capacity like no other. And with ongoing research & development, I am excited to be collaborating with new manufacturers from Belgium and the UK to create a wider range of material and production technology for the upcoming collections.

Is there anyone in the future you would want to collaborate with?

The list is too long! There are loads of designers and artists I would love to work with, even film directors! Sure love to collaborate and design custom pieces for Mr.Besson’s films!

How do you see fashion in the future? We are going through a real nostalgic period.

Fashion will become more “individualised” I think. With media information available on the internet, consumers will continue to be more educated on their purchasing choice.

What role does 3D Printing have?

It does make the production chain much friendlier. Instead of having endless meetings with multiple manufacturers working out designs and/or hair-pulling sessions on production matters, I am able to control the whole process with just a computer, anywhere in the world. Results are back in no time compared to traditional techniques, not to mention the complete accuracy it offers. There are also designs that are virtually impossible to achieve with traditional molding techniques, say, complex tunnels inside a complete enclosed structure for example. It is also ‘ecofriendly’. As traditional manufacturing methods involve materials being “taken” or “carved” away until the desired shape, 3D printing is completely opposite. It adds to create instead. That means zero wastage, which is great news for our planet earth. The products are also printed on demand, so no extra stock wasting around.

How is your design studio different from a typical atelier?

The atelier involves computers, 3D printers and 3D scanners. Not the typical atelier as one would imagine. Well, with today’s technology, I am able to communicate with my 3D designers, manufacturers and logistics all via the internet. The work flow is both smoother and more efficient, with excellent product quality achieved through global sourcing.

Your work is super high tech, men stereotypically like gadgets and technology. Have they been grasping your work?

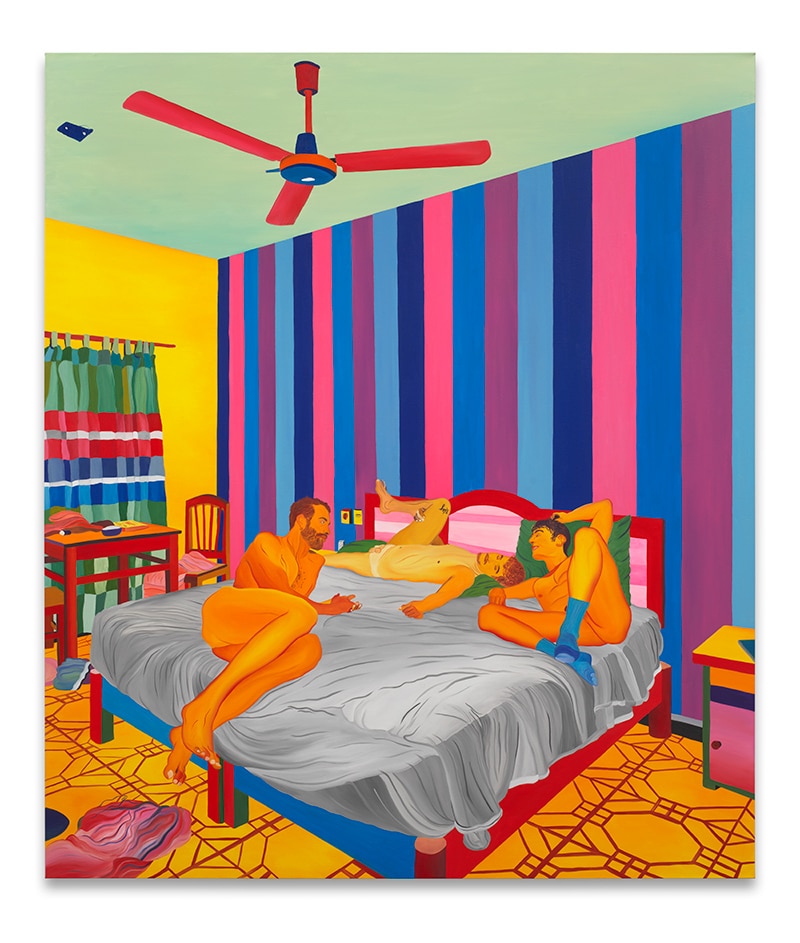

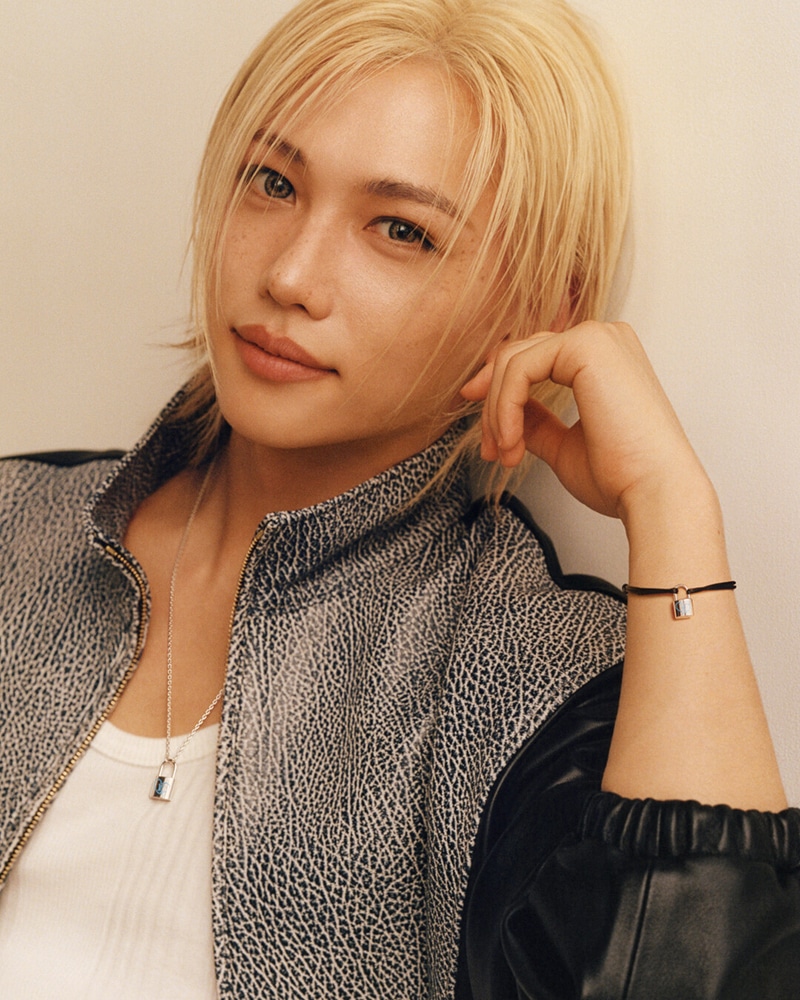

Male friends have all been intrigue by this whole concept, as they do like their gadgets and toys. But this technology is beyond grabbing the attention of stereotypical male. I have had elegant madams with Birkin handbags to male couples all showing great interest in the products. This concept is really for everybody I think, without boundaries. So to celebrate this with a modern approach, a wedding band series for couples of all sexual preferences will be introduced in the upcoming collection. Wedding sets include ‘For him & her’, ‘For her & her’, as well as ‘For him & him’.

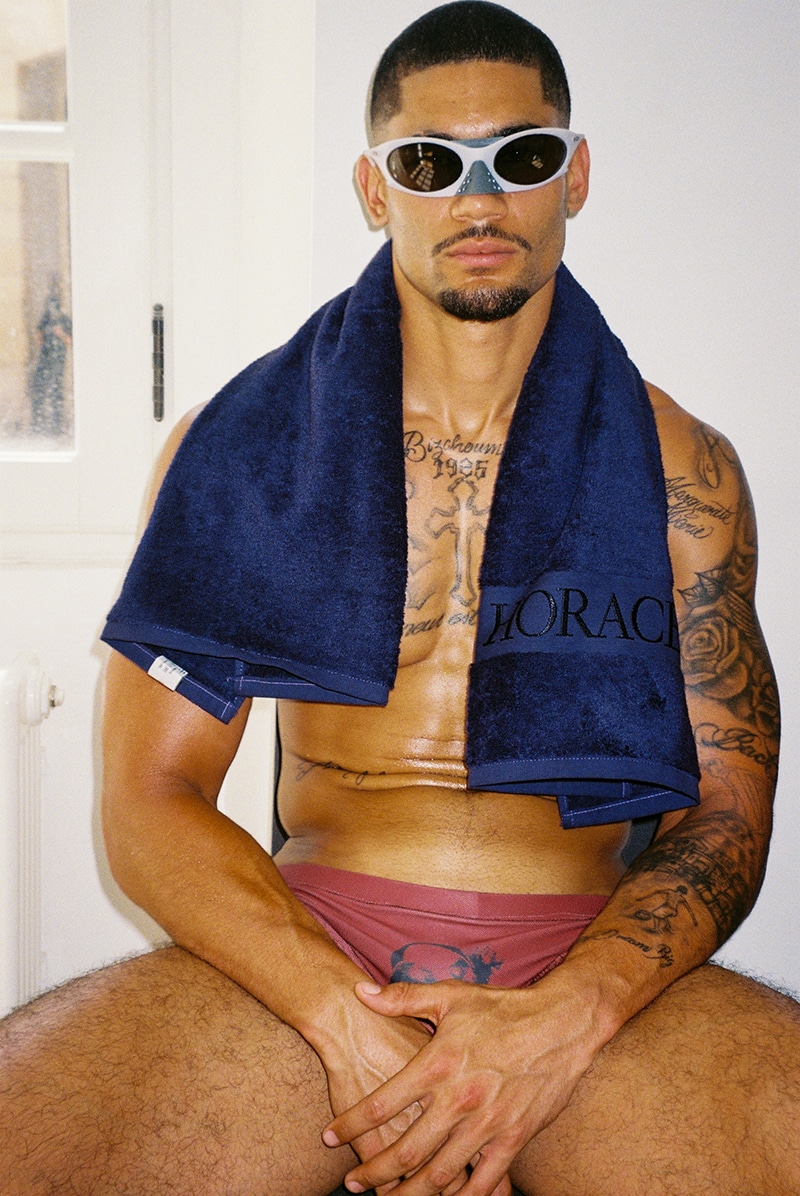

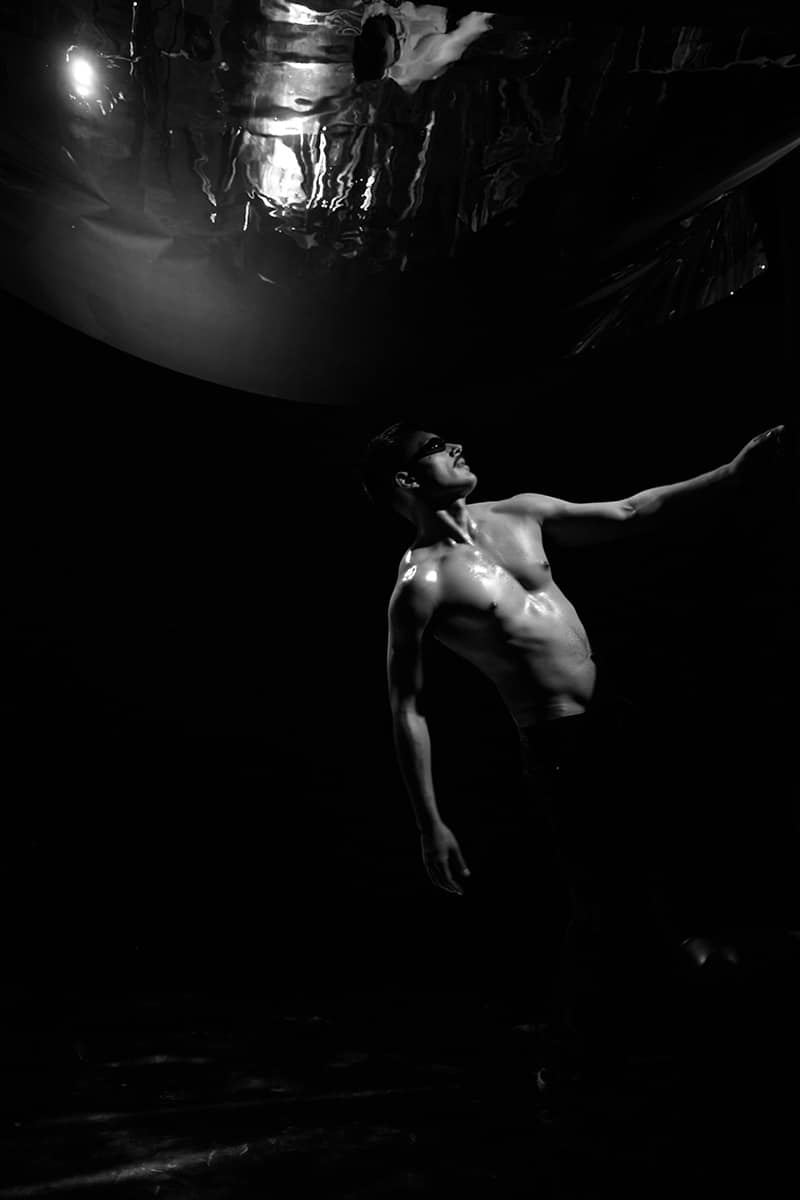

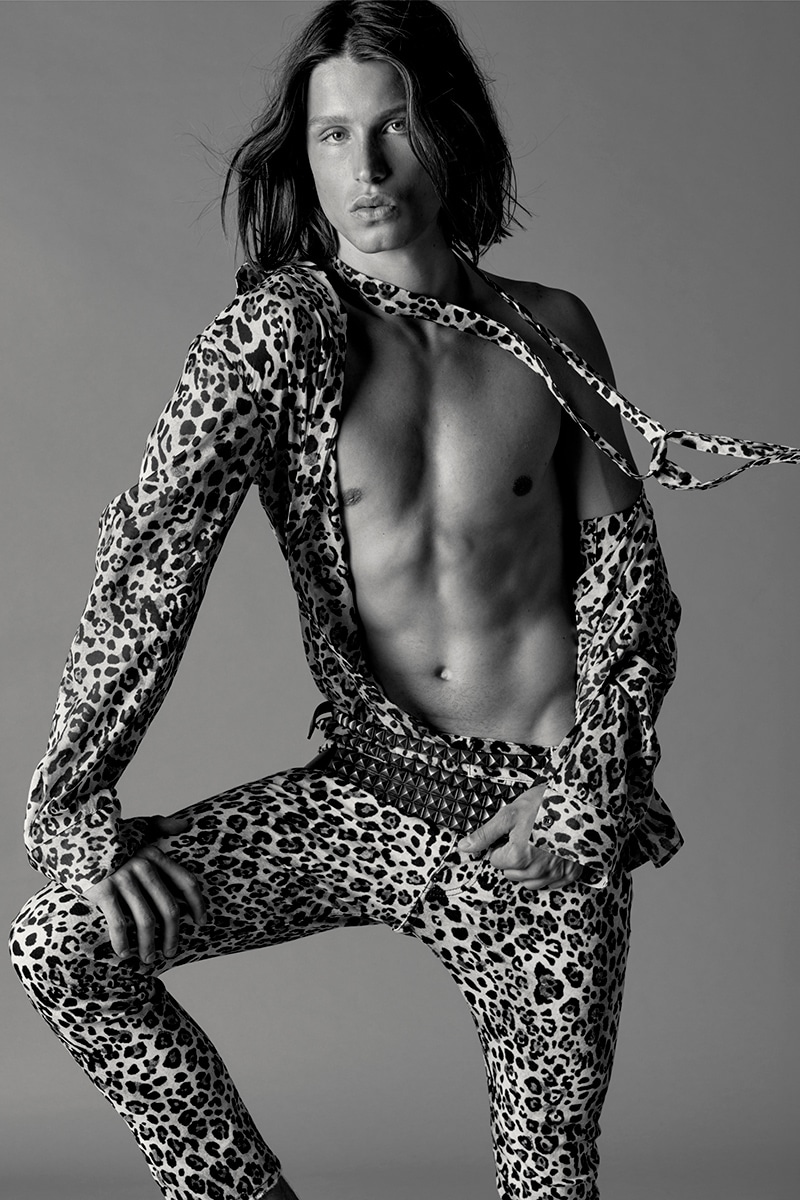

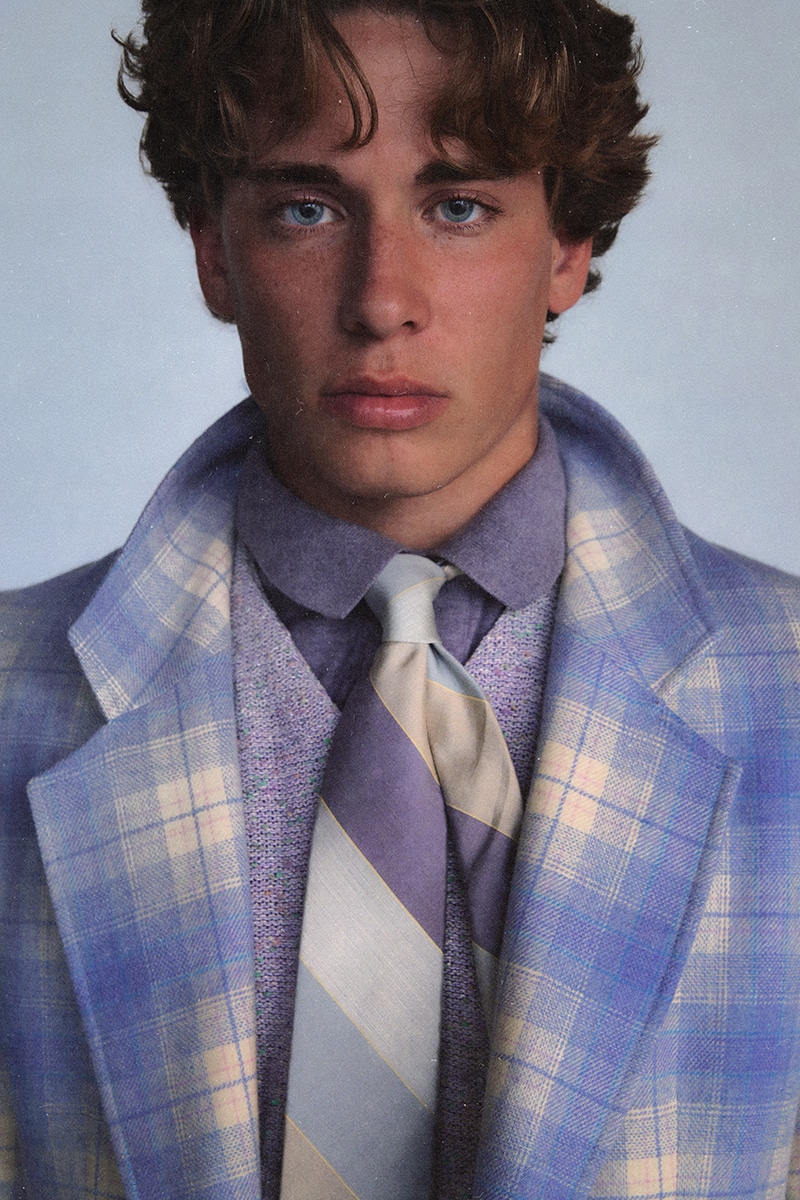

CREDITS:

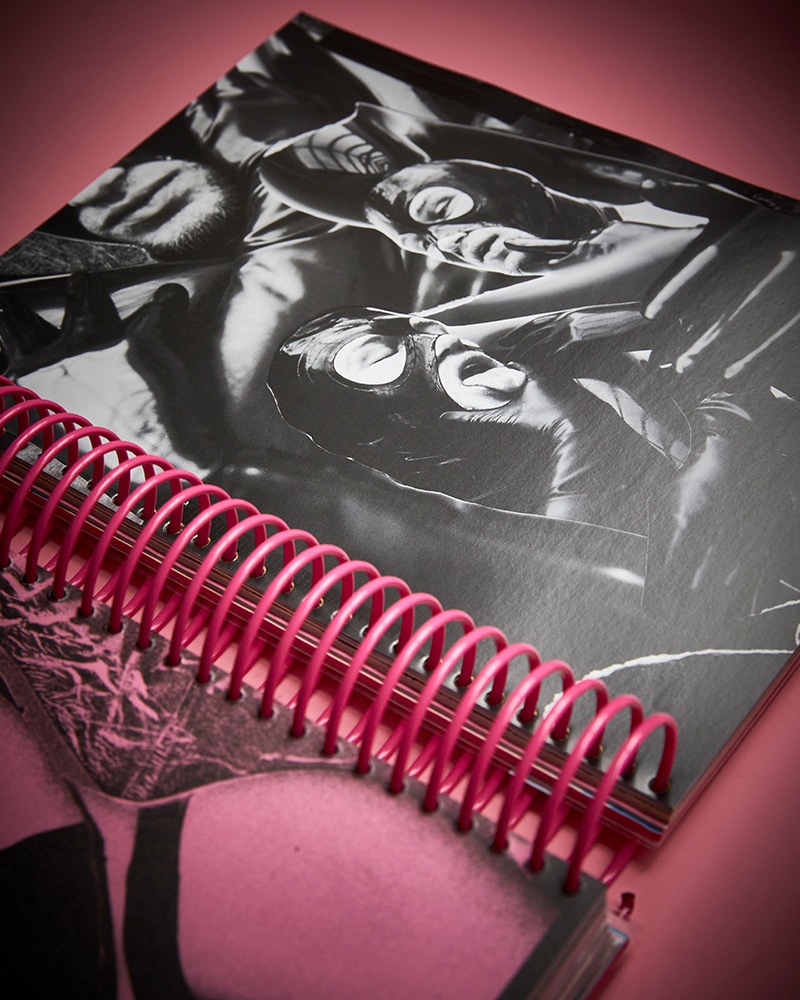

Diana Law 3D Printed Accessories

35mm Photography by Céline Bischoff

Production by Deila Vogur

Styling by Laetitia Gimenez

MUA: Yvane Rocher

Models: Mehdi, Jordan, Nordine and Liza